- enquiry@metalministry.in

- +91-9892171042

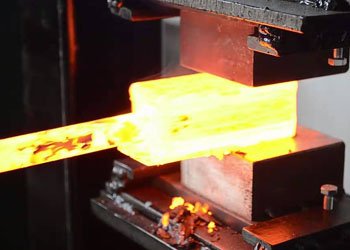

We at Metal Ministry Inc. engaged in manufacturing Inconel 738 Forgings that are fabricated from the raw materials and as per the quality standards. Inconel 750 (also known as UNS N07750) is a nickel-chromium alloy, blended with aluminum and titanium to make it precipitation-hardenable. It is corrosion and oxidation resistant and has good mechanical properties at elevated temperatures up to 700°C (1290°F), including high tensile and creep-rupture strength.

Our Inconel 750 Forged Products are accessible to our valuable customers in different range of diameters, wall thicknesses and sizes in customized form and also at quite affordable rates.

| Inconel 750 Forged Fittings | Inconel 750 Forged Round Bars |

| Inconel 750 Forged Hex Bars | Inconel AISI 750 Forged Elbow |

| AISI 750 Inconel Forged Flanges | Inconel 750 Forged Stubends |

| Inconel UNS N07750 Forged Caps | Inconel UNS N07750 Forged Fasteners |

| Inconel AISI 750 Forged Billets | Inconel AISI 750 Forged Reducer |

| Inconel UNS N07750 Forged Tee | Inconel 750 Forged Pipes |

| Inconel 750 Forged Tubes | Inconel UNS N07750 Forged Circles |

| Inconel 750 Forged Square Bars | Inconel 750 Forged Valves |

| Inconel AISI 750 Forged Flat Bars | Inconel UNS N07750 Forged Shafts |

| Inconel 750 Forged Rings | Inconel 750 Forged Discs |

| Inconel AISI 750 Forged Blocks | Inconel UNS N07750 Forged Extrusions |

| Inconel 750 Forged Custom Shapes | Inconel AISI 750 Forged Machined Parts |

Also known as UNS N07750, our Inconel 750 Forgings are accessible to our valuable customers in different range of diameters, wall thicknesses and sizes in customized form and also at quite affordable rates.

| C | Carbon 0.08 max |

| Mn | Manganese 0.30 max |

| S | Sulfur 0.010 max |

| Si | Silicon 0.50 max |

| Ni(+Co) | Nickel Cobalt 70 min |

| Cr | Chromium 14.0/17.0 |

| Co | Cobalt 1.00 max |

| Cu | Copper 0.50 max |

| Al | Aluminium 0.40/1.00 |

| Fe | Iron 5.00/9.00 |

| Ti | Titanium 2.25/2.70 |

| Cb + Ta | Columbium + Titanium 0.70/1.20 |

| Element | Inconel X-750 |

| Density | 8.28 g/cm3 |

| Melting Point | 1393-1427℃ |

| Tensile Strength | 1267 |

| Yield Strength (0.2%Offset) | 868 |

| Elongation | 25 |

| Hardness (Brinell) | ≤400 |

Metal Ministry Inc. exports Inconel 750 Forged Products to Mumbai, Thane, Navi Mumbai, Pune, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, New Delhi, Bengaluru, Chennai, Surat, Bhopal, Ulsan, Faridabad, Houston, Dubai, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, London, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Muscat, Edmonton, Busan, Mexico City, Doha, Jeddah, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Melbourne, Madrid, La Victoria, Bogota, Lahore, Los Angeles, Algiers, Chiyoda, Ankara, Ho Chi Minh City, Toronto, Hong Kong, Rajkot, Brisbane, Petaling Jaya, Ernakulam, Secunderabad, Gimhae-si, Al Jubail, Port-of-Spain, Thiruvananthapuram, Milan, Atyrau, Lagos, Hanoi, Howrah, Sydney, Ahvaz, Karachi, New York, Caracas, Vung Tau, Al Khobar, Manama, Montreal, Granada, Courbevoie, Visakhapatnam, Ludhiana, Moscow, Dallas, Haryana, Colombo

Metal Ministry Inc. exports Inconel 750 Forged Products to India, Saudi Arabia, Bangladesh, United States, United Arab Emirates, Canada, Angola, Argentina, Austria, Azerbaijan, Pakistan, Peru, Chile, Spain, France, United Kingdom, Indonesia, Israel, Iran, Kuwait, Mexico, Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile, Venezuela, Ecuador, Netherlands, Brazil, Colombia, Ghana, Iran, Denmark, Poland, Australia, Afghanistan, Bahrain, Costa Rica, Egypt, Iraq, Jordan, South Korea, Kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Poland, Qatar, Russia, Vietnam, South Africa, Nigeria, Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Bolivia, Bulgaria, Croatia, Czech Republic, Estonia, Finland, Greece, Italy, Japan, Libya, Romania, Thailand, Trinidad & Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya, Lebanon, Morocco, Mongolia

All our Inconel 750 Forged Products can be available with Black & Bright Surface as well as Finished surfaces. All these products are available with Relevent Mill Test Certificates, Heat treatment along with UT testing or NDT testing as required by the clients.